An Old/New Friend Drops By

We have transformed a few Bullitt Mustangs here and it has always been a delight to complete them and watch the owners enjoy a completely new ride for the better.

We have used many of the Whiteline product developed specifically for those Mustangs as well as Steeda light weight springs and adjustable strut mounts.

The other day we heard from Chef Marc who was becoming the new owner of one of these Bullitt projects.

Marc had read about our project Mustangs on another blog and contacted us to find out if the car was indeed the one he planned to purchase. We checked the serial number and sure enough, it was the one.

Marc had read about our project Mustangs on another blog and contacted us to find out if the car was indeed the one he planned to purchase. We checked the serial number and sure enough, it was the one.

Chef Mark is from Charleston, SC and has a restaurant there called Circa 1886. He is also a member of the local Mustang club, and two of the members came with him to help him and check out his "new" ride.

It was great to see the Bullitt Mustang at our shop again and greet the new owner. Test drives had been done by Marc and the two members of the club that had come with him and everyone seemed to be impressed with the handling of this car.

We love to improve our customer's cars as well as help keep them well maintained. Stop by and ask us what we would recommend for your car.

AP&C goes to PRI 2015

You may not know what PRI is, but you might know what SEMA is. SEMA is the secondary equipment manufacturers association and does much to promote aftermarket enhancements for your car as well as protect your rights to modify your ride. PRI stands for Performance Racing Industry is a similar show and is even owned by SEMA, but it is only open to people in the racing industry and is held once a year in Indianapolis, Indiana.

This year Automotive Performance & Chassis joined the thousands of attendees and explored a million square feet of exhibit space so that we could see some of the products and services that are available for our customers that enjoy racing and track days.

Here is a sample of the thousands of suppliers that we met with so that we can provide you with the kind of technical solutions you may be looking for.

Stainless Steel Brake Company is one of those suppliers that started out with a solution and built a huge business.

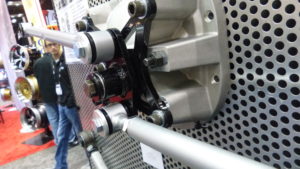

Alcon is another brake manufacturer that we often look to for upgrades on BMWs.

Another popular brake upgrade company is Wilwood.

So is StopTech:

Another brake supplier that is often optioned on OEM cars is Brembo:

If your are upgrading or optimizing your brakes let's not forget the lines...

For those of you that spend time at VIR here are some products to interest you as a driver or team:

AP&C has done a lot of work to improve the suspensions of our customer cars. One of our best sources of effective suspension modification hardware is an Australian company called Whiteline. They have products for Mustangs, Subaru, and other popular makes.

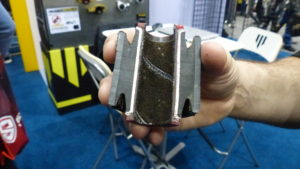

They have a line of uprates suspension bushings that don't require lubrication.

Above is a Watts linkage conversion for solid axle Mustangs.

Stainless Works makes some excellent headers and complete exhaust systems:

As well as some handy items...

Stage 8 makes some fool-proof solutions for header bolts:

Let's not forget the header and exhaust wrap...

There are many vendors for many products that you, our customers are interested in so here are a few more photos of just a few that we saw and met with.

AP&C does what it takes to stay in touch with the latest products available to the performance enthusiast as well as what it takes to keep your daily driver in top shape. We hope you enjoyed the look at this exclusive event in Indianapolis.

Seeing the Lights

Headlights have gone through a tremendous change from the ones that were mandatory in the 1960s and 1970s. It has allowed car designers to develop much more aerodynamic body style and even improve night time driving for us.

With these free-form headlights have come some problems, too. You've seen it yourself as time goes on many of these headlights turn milky and dull. It not only doesn't look very good, it impacts how well our headlights show us the way at night and in the rain.

Our shop truck is no exception. Over time our headlights have evolved from stylish helper to an ugly pair of headlights that just don't do their job.

We've seen and tried many of the restorative methods at our shop. They have ranged from simple wipe-on towels to elaborate polishing kits. Frankly, nothing is as effective as replacements. They clear up the problem and last for years, not just months.

We just replaced the fogged lenses on our shop truck and it has made a huge difference in illumination and taken years off the look of our truck.

If your car is suffering from the old headlight syndrome, let us restore your lighting and looks with a new set of headlights.

It is That Time of Year - Your Cooling System

Actually its always that time of year when you should have a health check-up done on your cooling system.

Many of us who live in the southern climes tend to think about our cooling systems when the hot months occur. But we need to keep in mind that this important system operates all year 'round and is vital to our motor's operation as well as our seasonal comfort.

This system performs many different functions including keeping our engine at the ideal operating temperature. How does it do this? Well, it not just water flowing through the radiator.

Antifreeze is part of the system that actually raises the boiling temperature of the water content that, when mixed together, becomes the coolant that is pumped around the engine, radiator, and heater core.

This magical elixir not only raises the boiling point of the coolant mixture, it provide lubrication to the water pump, an integral component of the cooling system.

Many car companies have their own specific formulations of antifreeze and some are supposed to last for 100,000 miles.

Another important feature of the cooling system is that it is pressurized. By keeping the closed system under pressure the boiling point is further raised. You see, car company engineers have determined that to get the best fuel efficiency out of a modern motor the engine temperatures should not be too cool. Keeping the coolant pressurized allows the temperature of the block to stay in an efficiency zone that is higher than the normal boiling point of water.

There are at least two radiators in your car that carry the coolant. One is the familiar large rectangle behind the grill.

The other is on the other side of the firewall, usually somewhere behind the glove compartment. That second one is the heater core. It is a small radiator that allows you to keep the interior warm in the winter and the windshield clear of frost and condensation.

So you have very hot fluid coursing about the engine, interior and just behind the grill under pressure and performing many functions from cooling, to heating, to defrosting, to lubricating, and we conveniently take it for granted - until it has a failure.

But it doesn't have to be that way. Many problems can be spotted before they terminate your commute. All those hoses can be checked for signs of deterioration, the radiator can be pressure tested, and the coolant can be tested for its ability to act as an anti-freeze.

If your car uses a cogged timing belt and its time to have it changed out, you will probably hear us recommend that you change out the water pump as well. While it may sound like we are pumping up your bill, we are actually trying to save you some money as the labor to replace the water pump separately is often just the same as doing the timing belt replacement.

Feel free to wait until the hotter months or come in before winter to have your cooling system checked along with its components. It can buy you some peace of mind when you take that long holiday road trip.

M3 Enhancement at AP&C

BMW introduced the M3 with it's E30 series cars and that version continues to be a model that is much sought after. Today the next generation of the "3" series was brought into the shop. It is the E36 M3 and a really beautiful example.

BMW introduced the M3 with it's E30 series cars and that version continues to be a model that is much sought after. Today the next generation of the "3" series was brought into the shop. It is the E36 M3 and a really beautiful example.

The owner has already invested a lot of time and money with well chosen enhancements to a car that was exceptional when it left the factory. Some great 'coil-over' shocks and a set of adjustable rear control links.

Here you can see the factory arms that were replaced.

We would also add a set of camber plates to the front struts. From the factory, the strut mounts come with a good amount of caster and camber built in, but these new camber plates would allow for a precise alignment that would allow for adjustments that would provide greater grip and an enhanced track-day experience.

Camber is the tilt of the wheel and negative camber describes where the top of the tire tilts in toward the chassis and the bottom of the tire is out father than the top. Properly done this setting provides added grip and stability. Much like going from standing with your ankles together to having your feet spaced apart. Done badly and you end up with unwanted tire wear, stress on suspension components, and a tail happy car.

Caster is a measurement of the tilt of the front spindle as seem from the side of the car. Positive caster describes where the top pivot point it closer to the firewall than the bottom.

What this tilt does is to add camber to the front outside wheel in a turn as well as aid the steering to return to center as you come out of a turn. When caster is equal side-to-side the car tracks nicely. One other benefit of increasing caster is that it acts as an invisible ramp that resists the normal dive of the front end as you apply your brakes when trying to stop. When done correctly this enhances handling.

The strut assembly is placed in our strut compressor and the spring is locked in and compressed so that the stock strut mount can be removed.

Then the camber plate is bolted in place of the factory strut mount. With its adjustable sliding plates it not only provides the function of a top strut mount, but it allows the technician to finely adjust the alignment.

With the strut assembly together the technician bolts the strut back in place and orients the new camber plate in the strut housing.

With an understanding of what the customer wants for handling the technician was able to provide an alignment to fit the owner's needs. These modifications to the car would provide maximum grip and precise handling without compromising tire wear or ride comfort.

We at AP&C enjoy working in partnership with our customers to help them meet their performance goals and avoid problems that can come with after-market parts.

We can also provide service and advice on the maintenance of your daily driver. Helping you to schedule appropriate service maintenance and evaluating the health of your transportation. Give us a call.

Corner balancing and alignment - track car prep

The Mysteries of Corner Balancing Revealed

One of the services performed at AP&C for our track enthusiast customers is corner balancing. For the uninitiated this term is not the least bit intuitive. So let’s go to a restaurant.

How many of us have been sitting at a table with our friends enjoying dinner or even just a cup of coffee and become annoyed by a table that rocks. As one of you leans on the table it moves and spills your coffee. You would reach for a book of matches to shove under one of the table legs, but no one smokes any more. So you move the table around or find a substitute to jam under the short leg so that you can get back to your coffee and conversation without being interrupted by a tilting table.

The same sort of thing can, and does occur on track with a race car. Absurd, you say. How can that be when each wheel is supported on springs? Aren’t all the tires touching the road all the time?

Yes, at rest, they are all touching, but they are not always carrying their fair share of the load. Like the rocking table, one corner may be carrying less of the load than another. To find out we place a set of specially designed scales under each tire to see just what is going on with static weight distribution. We find out that most cars are heavier at one end than the other. This is to be expected since there are large heavy objects, such as engines and transmissions that are not all crowded in the middle of a chassis. In most cases more weight is on the front of the car’s chassis than on the rear.

So how do we figure out which corner of the car is not carrying its fair share if the car is not perfectly balanced in the first place? Instead of trying to get the weight balanced on the chassis as a whole we can figure out how well the car is balanced by measuring the cross weights. That is the sum of the right front weight with the left rear vs. the sum of the left front and right rear and then look at the percentage of total weight the cross weight is. Ideally we would like to see 50%. That would tell us that corners are each supporting their proper share of the car’s total weight.

“So what?” you might ask, “The car is already suspended on springs and they will adapt as the car corners and weight transfers.” That is true to a degree, but on a race track consistency is paramount to being competitive as a driver and an unbalanced car will behave differently on a right hand corner than it will on a left hand corner.

Back to the garage. We have a track car with springs and shocks that allow for ride height and preload to be adjusted. These are often called coil-overs, where a coil spring is mounted on a threaded shock absorber with adjustable spring perches. These allow for changes in weight distribution on each corner.

Let's say that we have a race car that weighs 2000 pounds with a full load of fuel and a driver. If it were the ideal race car we would probably like to see that the scales under each tire show that they are each carrying 500 pounds of weight. Realistically, in the real world, we might see weight distribution more like this:

650 600

390 360

Telling us that 1250 pounds of the car is at the front and 750 pounds is at the rear.

If we sum the diagonal weights we get 1010 pounds for one diagonal and 990 for the other. In percentages that is 50.5% and 49.5%. Close, but not ideal. The right rear is not carrying its fair share and this race car will not handle consistently on right and left hand turns.

While we can’t just shove a match book under the short leg we can change the ride height of each corner and get the car back into balance. So we can first start with the light corner and lengthen it by changing the ride height. The threaded shock absorbers allow us to do just that. With them we can add a little less than another quarter inch to the ride height on the right rear. After the car is settled and we roll it onto the scales again we find that the weights have changed and are now:

630 575

420 375

We are getting closer with the percentages now 50.25% and 49.75%. We could either add just a bit more to the right rear again or we could take away a bit from the left front corner. So we shorten the left front just a tiny bit and get these results:

628 583

417 372

Now we are at the perfect 50% cross weight and we will have a happier driver who now has a more consistent handling track car.

Corner weighting is just one aspect of getting a track car to perform at its best for a driver. The suspension also needs to be adjusted and aligned so that maximum grip can be obtained at the tire patches. Tire pressures, spring rates, anti-roll bars, weight distribution, and many other factors will limit or enhance handling performance.

AP&C has the tools and the experience to help you achieve your goals on a road racing track whether it is to prepare your street car for a weekend of HPDE (high performance driving education) or to help you set up your track car for a Chump Car event. Drop by or give us a call and we will work together to help you get the most out of your ride.

Dual disk clutch install on C5 Corvette Z06

We installed a Mcleod RST 9.5" dual disk clutch in this 2002 C5 Z06. While the factory clutch was still holding, with 120,000 miles on the clock, this was both preventative maintenance to freshen up the car, and a solid foundation for future horsepower building plans of the owner including the potential for a supercharger. There are a wide variety of clutch options available, including a stock replacement 10.5" clutch good to about 450hp or an upgade to the LS7 11" clutch with additional headroom over 600hp. Larger diameter driven disks have more friction area, but along with the larger pressure plates, can add additional weight and rotating mass. High performance pressure plates with higher plate loads can accommodate higher horsepower, but bring increased pedal effort.

We installed a Mcleod RST 9.5" dual disk clutch in this 2002 C5 Z06. While the factory clutch was still holding, with 120,000 miles on the clock, this was both preventative maintenance to freshen up the car, and a solid foundation for future horsepower building plans of the owner including the potential for a supercharger. There are a wide variety of clutch options available, including a stock replacement 10.5" clutch good to about 450hp or an upgade to the LS7 11" clutch with additional headroom over 600hp. Larger diameter driven disks have more friction area, but along with the larger pressure plates, can add additional weight and rotating mass. High performance pressure plates with higher plate loads can accommodate higher horsepower, but bring increased pedal effort.

As this car serves as a daily driver and sees rush hour stop and go traffic, the owner wanted to maintain near stock pedal effort while shaving weight for quicker revs and still adding greater power handling capability for the future. The dual disk kit uses twin 9.5" solid hub disks (no damper springs), a floater plate, and a diaphragm style pressure plate and is rated to 800hp.

As this car serves as a daily driver and sees rush hour stop and go traffic, the owner wanted to maintain near stock pedal effort while shaving weight for quicker revs and still adding greater power handling capability for the future. The dual disk kit uses twin 9.5" solid hub disks (no damper springs), a floater plate, and a diaphragm style pressure plate and is rated to 800hp.

We began by removing the exhaust system and torque tube shield, and then disassembled the rear suspension and brake components to allow the rear suspension cradle to be removed as an assembly while under car supports to hold the engine and transmission / trans-axle in place. There were many components to disconnect including shocks, sway bars, brakes, upper control arms, and various wiring and connections to the transmission and rear end.  With the rear cradle out of the car, we disconnected the clutch line, removed the shift knob and freed up some pieces in the console, and finally unbolted the torque tube from the bell housing and slid the entire assembly to the rear and safely lowered it with a transmission jack.

With the rear cradle out of the car, we disconnected the clutch line, removed the shift knob and freed up some pieces in the console, and finally unbolted the torque tube from the bell housing and slid the entire assembly to the rear and safely lowered it with a transmission jack.

The transmission showed some minor seepage of oil and the accumulation of 120k miles of dirt. The hydraulic release bearing was not leaking but the bearing showed significant radial slop and definitely was due for replacement. Next we removed the pressure plate, disk and flywheel from the engine while leaving the bell housing in place. Clearance to

the top bell housing bolts is extremely tight. Be sure to fully support the engine to avoid damage to the firewall and engine components.

With the flywheel out of the way, and ready to head to the machine shop for resurfacing, we noted minor oil seepage around a rear cover on the engine block. While it did not absolutely require replacement, this is a 15 hour job and the investment to clean the block and replace the seal along with installation of a new main seal and pilot roller bearing made sense as solid insurance against future troubles.

With the flywheel out of the way, and ready to head to the machine shop for resurfacing, we noted minor oil seepage around a rear cover on the engine block. While it did not absolutely require replacement, this is a 15 hour job and the investment to clean the block and replace the seal along with installation of a new main seal and pilot roller bearing made sense as solid insurance against future troubles.

The flywheel displayed only minimal signs of heat as did the pressure plate. The driven disk appear to have significant life left in it, a testament to the high quality materials GM chose. Additionally, the pressure plate appeared to contain more than your average amount of engineering with cooling vents stamped into the cover that would create air flow as the assembly spun.

The flywheel displayed only minimal signs of heat as did the pressure plate. The driven disk appear to have significant life left in it, a testament to the high quality materials GM chose. Additionally, the pressure plate appeared to contain more than your average amount of engineering with cooling vents stamped into the cover that would create air flow as the assembly spun.

The four double wound springs in the clutch disk help absorb drive line shocks and decrease gear rattle in the transmission. When moving to solid disks that do not contain these springs (as with our dual disk install) be prepared to hear more rotating gear noise from the rear of the car with the clutch out in nuetral, and some gear rattling noises when lugging the engine at low RPM, especially while accelerating from low speed (10-20 mph ) in 2nd or 3rd gear. This sound will only persist for a second or two, but should be considered in advance.

The four double wound springs in the clutch disk help absorb drive line shocks and decrease gear rattle in the transmission. When moving to solid disks that do not contain these springs (as with our dual disk install) be prepared to hear more rotating gear noise from the rear of the car with the clutch out in nuetral, and some gear rattling noises when lugging the engine at low RPM, especially while accelerating from low speed (10-20 mph ) in 2nd or 3rd gear. This sound will only persist for a second or two, but should be considered in advance.

While waiting for the flywheel to return from the machine shop, we cleaned the torque tube and transaxle assemblies, brushing the input shaft splines to remove any rust and ensure smooth engagement with the splines in the new clutch disks.

Next, we installed the new clutch release bearing.

Next, we installed the new clutch release bearing.

With the flywheel back and installed on the crankshaft, oriented in exactly the same position as when it was removed, we installed the gold adapter ring, the first disk, the floater plate, the second disk, and finally the new pressure plate. Be sure to use the alignment tool and install all components so that the index mark (in black) lines up.

This assembly was balanced at the factory, and this alignment mark ensures it will be balanced once installed. As there are factory production variances, some flywheels have additional weights installed in them and it may be advisable to have a machine shop balance the flywheel you plan to use (factory or aftermarket) along with your new clutch set to ensure smooth, vibration free operation.

This assembly was balanced at the factory, and this alignment mark ensures it will be balanced once installed. As there are factory production variances, some flywheels have additional weights installed in them and it may be advisable to have a machine shop balance the flywheel you plan to use (factory or aftermarket) along with your new clutch set to ensure smooth, vibration free operation.

With the clutch assembly in place and correctly torqued, it was just a matter of putting it all back together and taking it out for a test drive. The clutch feel was very similar to stock, and the organic disks in the RST kit engaged smoothly with no chatter. There is a 500 mile break in period where normal mix of city and highway driving is recommended before the clutch is used for more performance oriented driving.

Variety is the spice of life

One of the things that I appreciate about being a part of Automotive Performance & Chassis is the wide range of vehicles we find in the shop from day to day. We might have a Porsche Boxster, a Classic Corvette Stingray, along with a Bullet Mustang, a crossover or SUV.

One of the things that I appreciate about being a part of Automotive Performance & Chassis is the wide range of vehicles we find in the shop from day to day. We might have a Porsche Boxster, a Classic Corvette Stingray, along with a Bullet Mustang, a crossover or SUV.

We might be rebuilding the cylinder head of a track Miata, and when a car like this is in the shop, I never get tired of looking at all the work that has gone into a finished product that represents countless hours of thought, trial and error to fit the right combination of pieces together from the protective roll cage, lightweight race seats and multi-point harnesses, to the removable steering wheel, and emergency battery disconnect switch.

Everything in a car like this has a clear purpose, and anything that doesn't serve the purpose of going fast safely has been eliminated to save weight.

I also appreciate modern, factory built performance vehicles like this Porsche. It is hard not to be a bit star struck when something like this, or even a Ferrari rolls in. This represents an automotive passion - it is rolling art not just a method of transportation. It is an experience.

I also appreciate modern, factory built performance vehicles like this Porsche. It is hard not to be a bit star struck when something like this, or even a Ferrari rolls in. This represents an automotive passion - it is rolling art not just a method of transportation. It is an experience.

The classics many of us grew up with have largely faded from view, so it is interesting when we have something like this Studebaker Cruiser in the shop. Today's cars are largely made of aluminum and plastics to save weight, and to improve safety. We have hybrid powertrains with Lithium-Ion battery packs, airbags in the dashboard, doors, and seats. We have satellite radios and GPS navigation systems with color LCD displays. Automatic transmissions now have 7, 8 and even 9 forward gears.

In contrast, this Studebaker provides a lense into times past when cars were made largely of steel, transmissions were manual shifts on the column and cruise control and air conditioning were optional features that often appeared to be retrofitted to, rather than designed into the car. I appreciate machines like this as treasured rolling time capsules, and am glad to see this owner investing to preserve this particular piece of history for himself and others in years to come.